Investigation of the reproducibility of a study design on the differences in the development of functional understanding when using functional analysis and synthesis-driven analysis

- Supervisor: Jonas Rode

- Supervisor: Dr.-Ing. Ingo Jonuschies

- Research area: Human Behaviour in Design

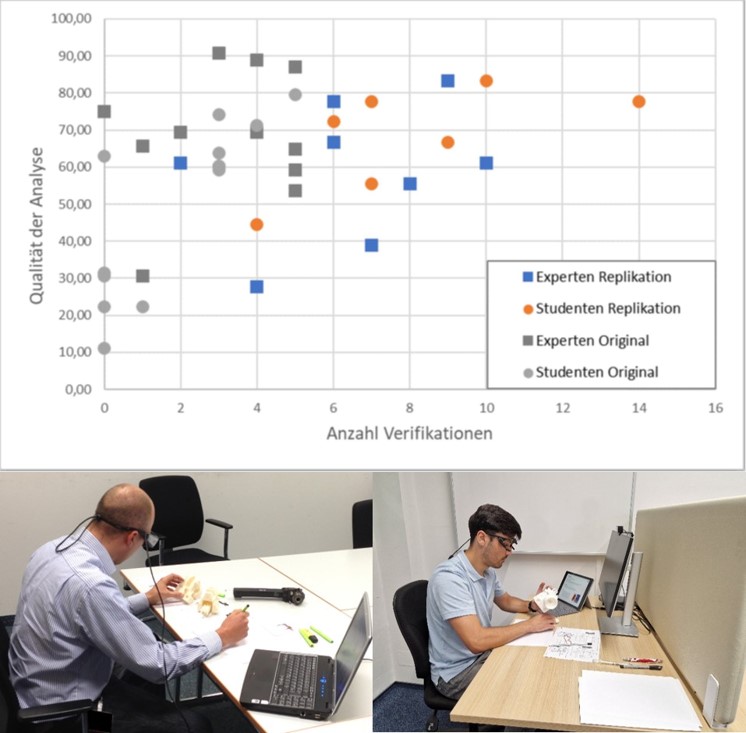

The aim of the work was to gain insights into the replication of studies in order to derive further measures for ensuring reliable results. A reference study from design research was selected for functional analysis and synthesis-driven analysis. In the first step, the reference study was analysed solely on the basis of its scientific publication and a study design for replication was developed on the basis of the analysis. In the second step, the replication study was carried out. The implementation and results were then compared with those of the reference study. On the one hand, statements can be derived as to whether it is possible to derive a feasible study design based on the underlying information. On the other hand, there are indications as to whether and in what way assumptions had to be made and how these can influence the results of the study. The main question here was whether the replication study was actually a replication of the original simply because it could be carried out.

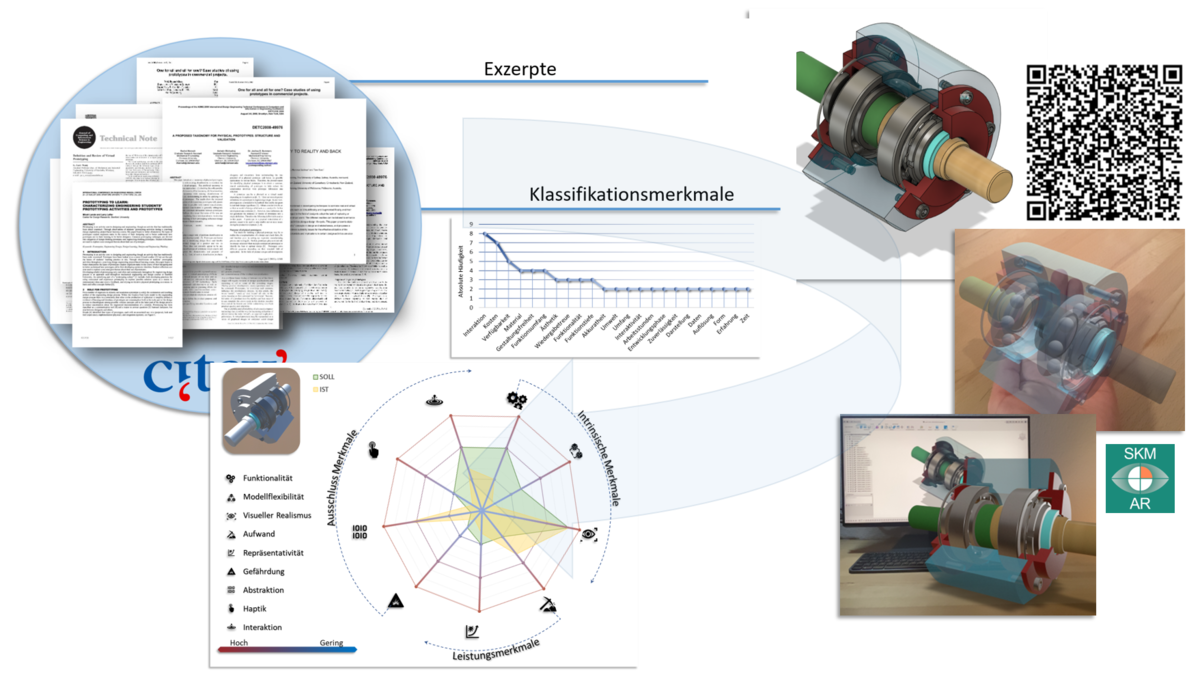

Investigation of classification approaches of virtual prototypes in product development - evaluation on self-created AR and VR experiences

- Author: Michael Hemmer

- Supervisor: Dr Stefan Zorn

- Research area: Prototyping

The aim of this work is the investigation of general characterising properties of virtual prototypes, which enables a categorisation. Furthermore, it is to be investigated in which form a generally valid evaluation of these properties is possible for different prototypes. The knowledge gained is to be applied to the example of a self-created virtual prototype (AR/VR experience) of a complex bearing assembly.

Development of a concept for extending the mobility of wheelchairs, focussing on additive manufacturing and lightweight construction

- Supervisor: B.Sc Oskar Friese

- Supervisor: M.Sc. Pascal Schmitt

- Research area: Methodological support for utilising the potential of additive manufacturing processes

A modular extension for wheelchairs for accessing sandy surfaces (beach) is to be developed. Market research and a user survey will initially be used to identify open user needs. A solution is then to be developed using a design methodology (VDI 2221 - 2225). The objectives of lightweight construction and additive manufacturing play a special role here. As a result, the preferred solution is to be realised constructively and as a physical prototype.

Development of a customised ergonomic triathlon trailer for production using additive manufacturing processes

- Supervisor: B.Sc Lukas Schnödewind

- Supervisor: M.Sc. Pascal Schmitt

- Research area: Methodological support for utilising the potential of additive manufacturing processes

The realisation of a trailer for triathlon bikes is to be rethought. The focus is on the use of AM and how its use can affect the boundary conditions, system limits and the entire product architecture. To this end, the current state of the art will be analysed and potentials identified. The approach of ‘Enhanced Function-Means modelling’ will be focused on in the redesign of the product architecture.

Potentials and hurdles for the use of functional near-infrared spectroscopy fNIRS in the field of design research

- Author: B.Sc. Martin Kersing

- Supervisor: Dr Stefan Zorn

- Research area: Prototyping

- Topic description

The functional near-infrared spectroscopy method, fNIRS for short, is a non-invasive imaging method that can be used to draw conclusions about brain activity in certain areas of the brain. Among other things, it is used to determine the cognitive load/utilisation of the brain during defined tasks. Based on the function and tasks assigned to the brain areas, decision-making processes or information processing can also be visualised.

For use in future research projects, scientific research is to be carried out on the possible potential in the context of researching the use of prototypes. In addition to the measurement fundamentals, the required technology and software, the basic procedure for analysing the measurement results will be examined in particular. Another essential component is the overview of research activities already carried out in the field of design research as well as research work in other scientific fields to investigate cognitive load/utilisation.

Development of AR exercise content to promote spatial imagination in engineering education

- Author: Yang Chen

- Supervisor: Dr Stefan Zorn

- Research area: Alternative visualisations of physical objects and their influence on spatial imagination

The aim of this work is to create augmented reality training content for the targeted improvement of spatial visualisation skills in engineering students. For this purpose, the current state of research regarding the use of immersive technologies such as AR and VR in engineering education is summarised. The insights gained in this way regarding AR exercise content, the forms of AR use and the type of exercise/teaching concepts are incorporated into the planning of targeted exercises. With the help of the SKM Publisher, own AR exercises are then realised and validated.

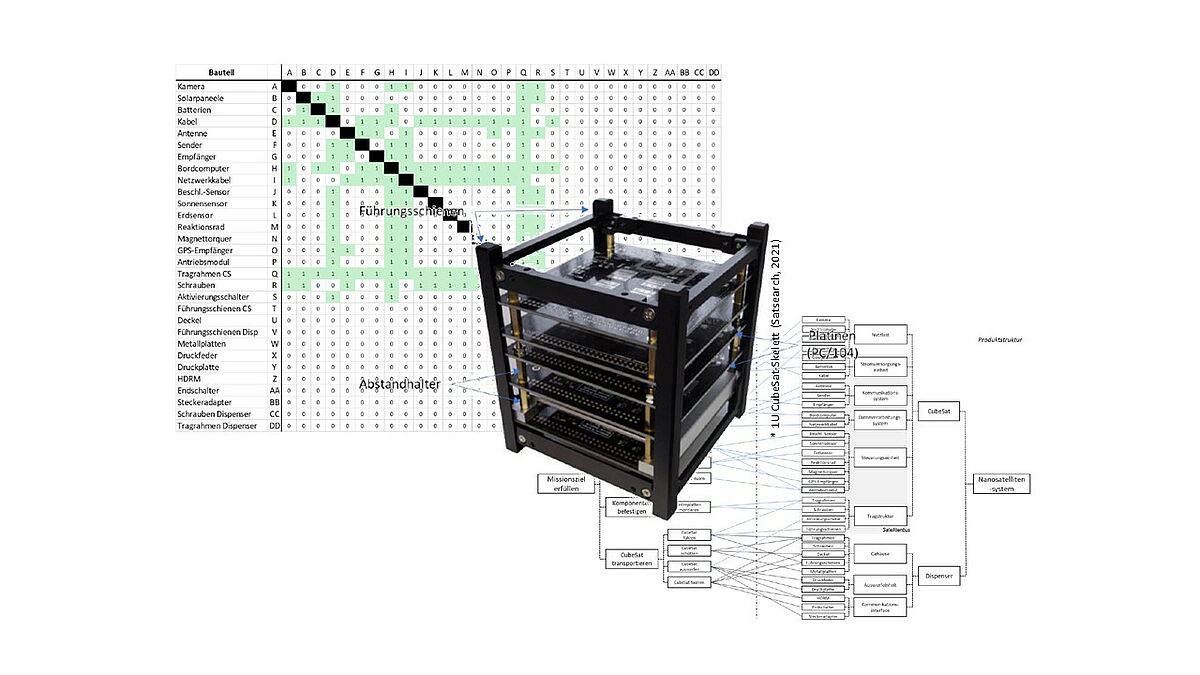

Design and additive prototyping of an innovative nanosatellite system

- Researcher: Martin Kersting

- Supervisor: Dr Stefan Zorn

- Research area: Prototyping

The aim of this work is to develop a concept for a novel small satellite system based on a central structure. The system consists of an ejection mechanism and one or more small satellites. The applicable norms and standards are to be compiled, requirements researched and existing solutions for satellites and ejection mechanisms analysed. The methodological approach to concept development must be documented. Furthermore, a feasibility assessment must be carried out for the preferred concept. The selected concept is to be prototypically realised using additive manufacturing processes. The equipment available at the chair can be used for this purpose.

Augmented reality and the influence on the development of spatial imagination in engineering education

- Author: Yang Chen

- Supervisor: Dr Stefan Zorn

- Research area: Alternative visualisations of physical objects and their influence on spatial imagination

The aim of this thesis is to provide an overview of measures for the development of spatial visualisation skills in engineering students. The focus is on the use of new media, such as augmented or virtual reality. The current state of research is to be compiled for this purpose. Based on this information, an existing study design is to be adapted. The aim is to specifically promote the development of students‘ spatial imagination (especially in the field of construction) and thus improve the students’ personal skills as well as teaching in general.

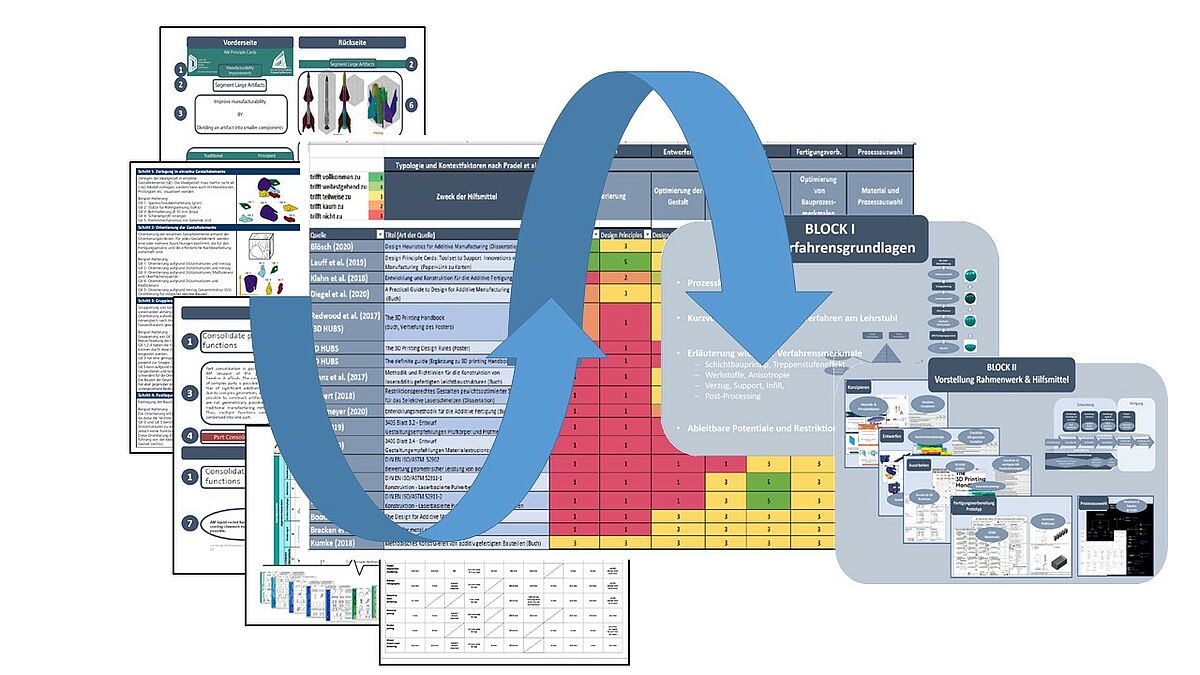

Overview of design-related methodological tools for additive manufacturing-compliant design

- Author: Rico Jaensch

- Supervisor: Dr Stefan Zorn

- Research area: Prototyping

The aim of this work is to compile an overview of currently available design-related methodological tools for AM-compliant design and to create a classification system. Furthermore, an illustrative exercise unit for students is to be designed for the AM devices available at the chair.

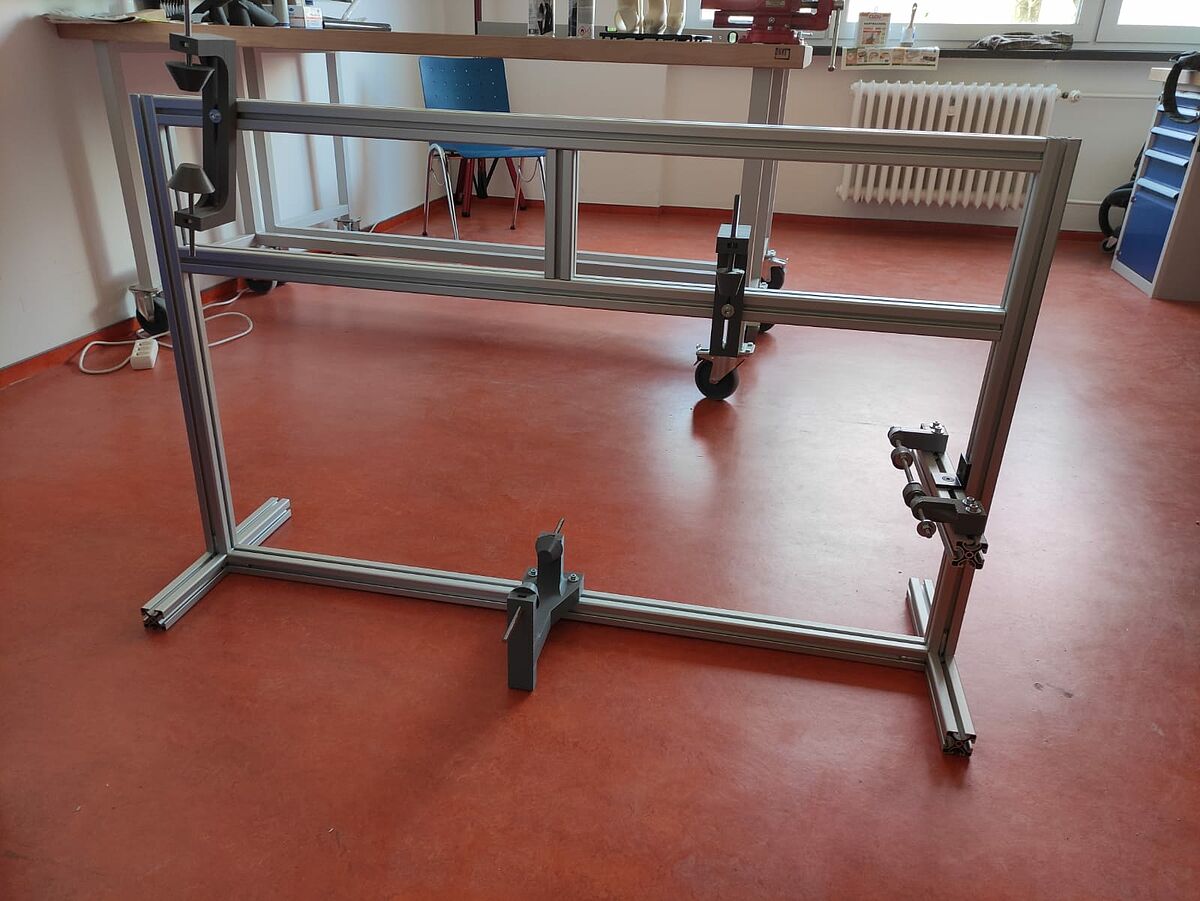

Commissioning of an existing test rig for determining the characteristic values of additively printed hollow clamping bushes

- Author: Tobias Glaser

- Supervisor: Pasal Schmitt

- Research area: (link to) 3D printed hollow clamping bushes

An existing test rig at the Chair of Product Development has been used in the past to determine the mechanical load values of 3D-printed hollow clamping bushes (see figure). These tests focussed on the production of hollow clamping bushes made of ABS using the FDM printing process. As part of this student research project, the existing setup of the testing device is to be put back into operation. To this end, the components and software are to be checked for maintenance backlogs and functionality. Once the test rig has been successfully commissioned, tests are to be carried out to determine the maximum transmittable torques and the tightness of the material. In addition to the existing tests, hollow clamping bushes manufactured using stereolithography or selective laser sintering are to be analysed.

Parameter study for prototyping with the help of ‘Fused Deposition Modelling’

- Researcher: Laith Sido

- Supervisor: M.Sc. Lisa Rößler

The aim of this work was to utilise the potential of printing anisotropic materials and to determine the optimal conditions for printing. For this purpose, test specimens were constructed, printed with different parameters and then evaluated. A parameter database was then created for prototyping with the MakerBot MethodX.

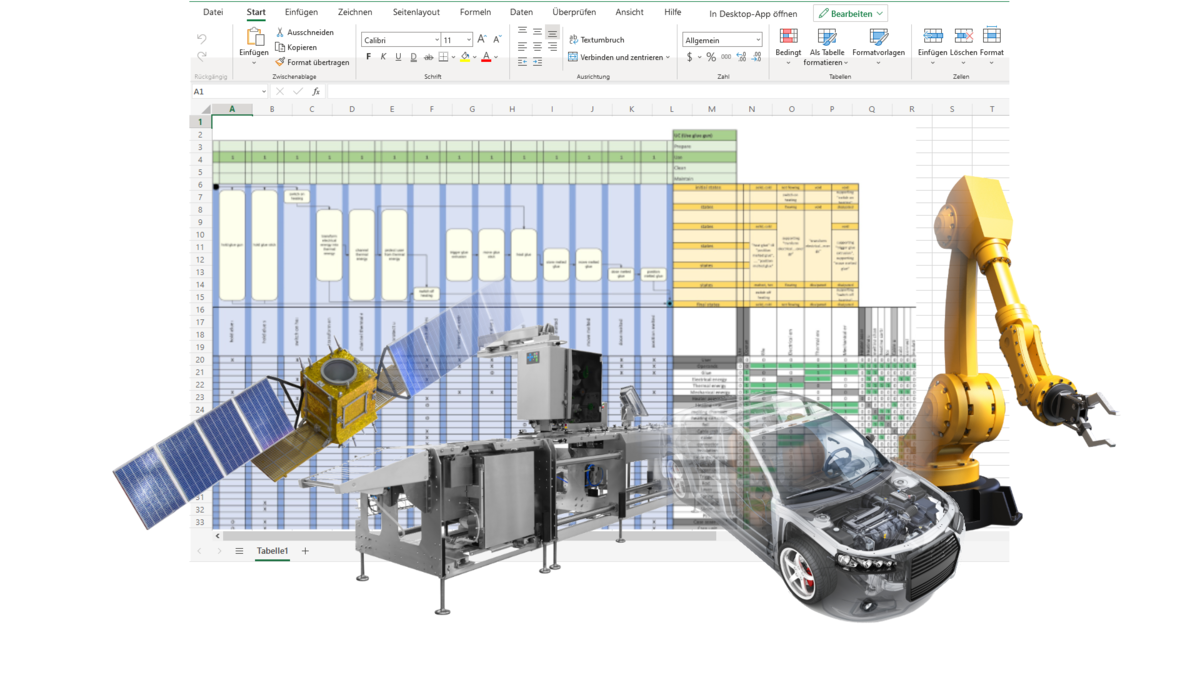

Development of a supporting tool for the application of ‘integrated function modelling’

- Author: Jonas Rode

- Supervisor: Dr Stefan Zorn

- Research area: Systems engineering and modelling

The aim of this work is to create a supporting tool for the application of ‘Integrated Function Modelling’. The IFM is to be analysed and the logic mapped using suitable forms. Based on this analysis, a macro-based template is to be created in MS Excel, which maps the logic and supports the user in the creation of an IF model.

Conceptualisation and design of a mechanically and self-propelled wheelchair lift

- Researcher: Chris-Maurice Clasen

- Supervisor: M. Sc. Pascal Schmitt

As part of the Bachelor's thesis, a concept is to be developed and designed that makes it possible to climb stairs with an active wheelchair using one's own physical strength. For the upward movement, a direct transmission of the rollers should function and for the downward movement, the potential energy should be used and braked to a defined speed. The aim of this project is to develop this concept and realise it as a digital prototype.

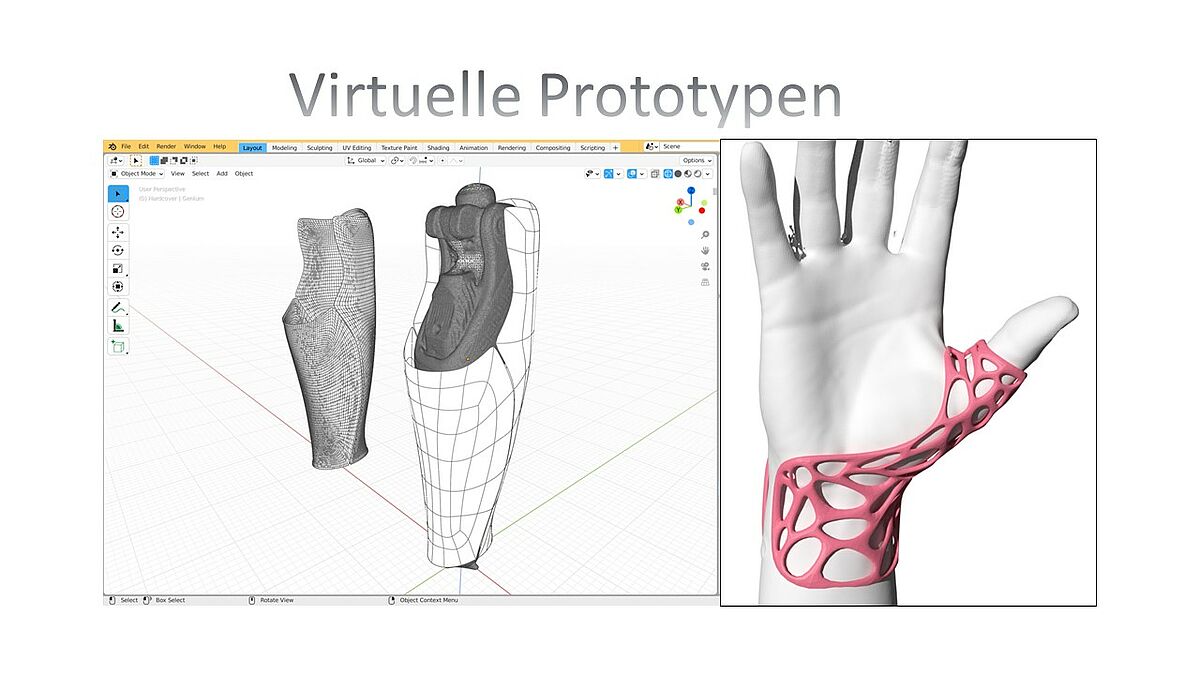

Creation and use of prototypes in the field of individualised medical aids

- Researcher: Cay Unverricht

- Supervisor: Dr Stefan Zorn

- Research area: Prototyping

The aim of this work is to analyse and compare the procedure for the creation of prototypes in the field of individualised medical aids depending on the intended use and the number of units to be produced. The properties of the virtual and physical prototypes used are to be characterised based on the Prototyping Navigator. Missing dimensions are to be added. The individualised production of orthoses and the creation of configurable coverings for electric lower leg prostheses serve as use cases in the respective scenarios. These are to be compared with the classic procedure for creating physical prototypes in these areas. The advantages and disadvantages are to be worked out. The AM devices available at the chair can be used to produce the prototypes.

Determination of parameters for the combination of additively printed moulds for casting

- Researcher: Franziska Grabe

- Supervisor: M. Sc. Pascal Schmitt

This thesis deals with a hybrid manufacturing approach. It combines additive manufacturing (3D printing) and a casting process. The aim is to combine the good properties of the processes.

As part of this Bachelor's thesis, parameters and boundary conditions for the printing process are to be determined and tested in experimental trials. To this end, criteria/requirements such as required wall thicknesses, inlet/outlet and tightness against resin leakage must first be worked out. Subsequently, the focus will be on the pressure parameters of the wall thicknesses of FDM printed components. A suitable test specimen is to be designed for this purpose and tested in a series of experiments.

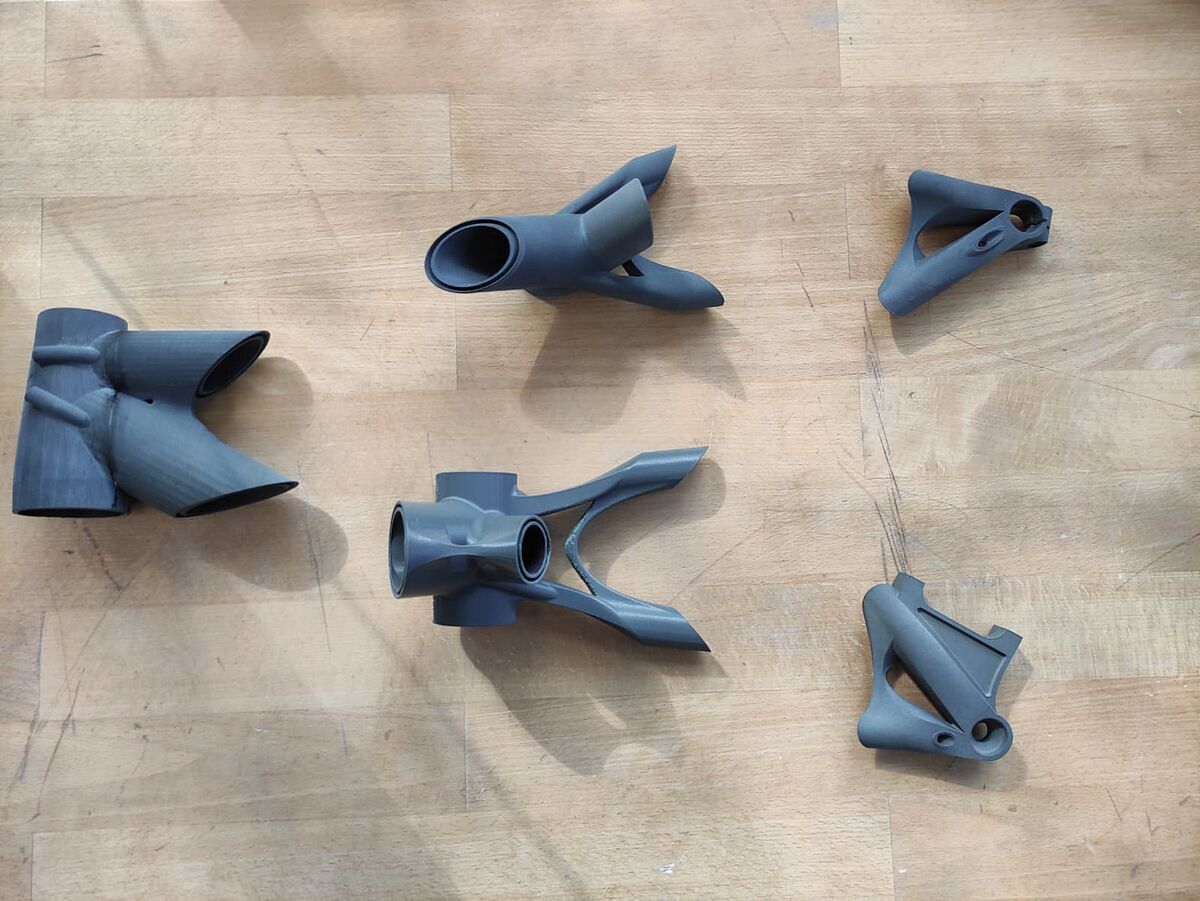

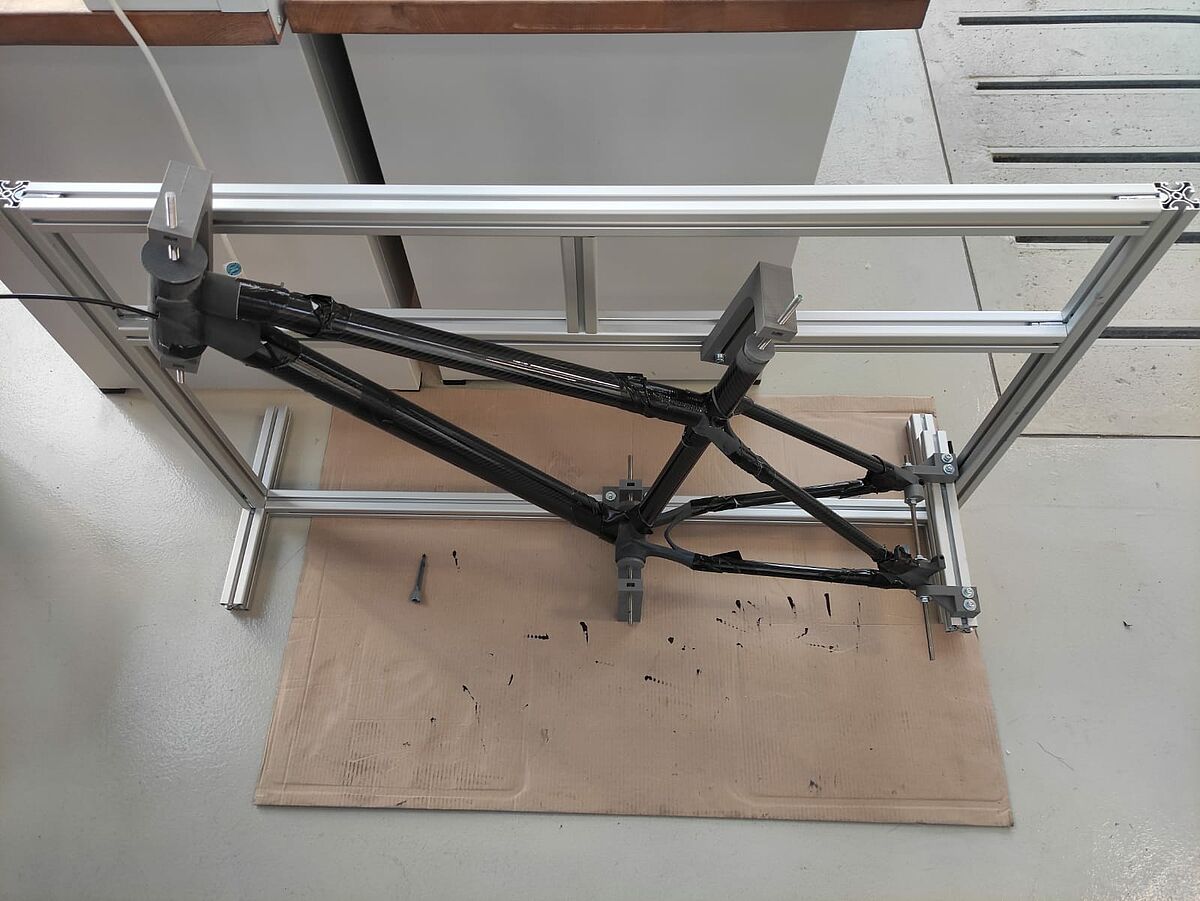

Design and construction of a bicycle frame from additively manufactured connecting components and semi-finished products

The aim of the project was to design and build a complete prototype of a bicycle frame in group work. Various concepts were developed over the course of the semester, taking into account modern standards, load cases and interfaces to purchased parts. The additive manufacturing machines available at the department, including filament 3D printers and nylon SLS 3D printers, were used to produce the prototype. The connection between additively manufactured connection components and the carbon tubes as semi-finished products was created by bonding. In order to hold the assembly in position during hardening, a frame construction jig was designed and built to accommodate frames of different sizes. Finally, the purchased parts such as the fork, handlebars, bottom bracket and wheels were assembled. This allowed the strengths and weaknesses of the concept to be analysed. You can see the results on the right.

Bell frame of St Peter's Church in Rostock

Students support the association with the model

Rostock. The steel bells of St Peter's Church are still ringing at the foot of the nave. ‘It's still the aftermath of the war. The sound of the bells is part of the city,‘ says Reinhard Wegener, Chairman of the St Peter's Church Friends’ Association.