A cost-effective and flexible alternative to conventional hydraulic clamping bushes

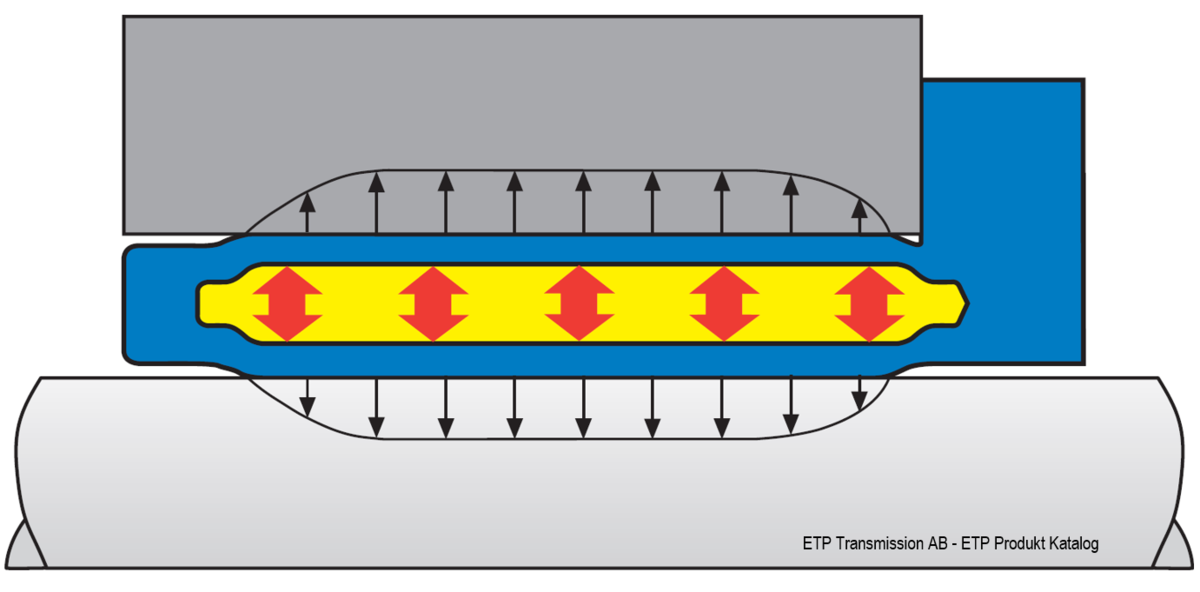

Operating principle of hydraulic clamping bushes

A hydraulic pressure medium is enclosed in a chamber and pressurized.

The pressure is distributed uniformly over the walls of the chamber.

The expansion of the chamber walls creates a uniform surface pressure between the shaft and the hub.

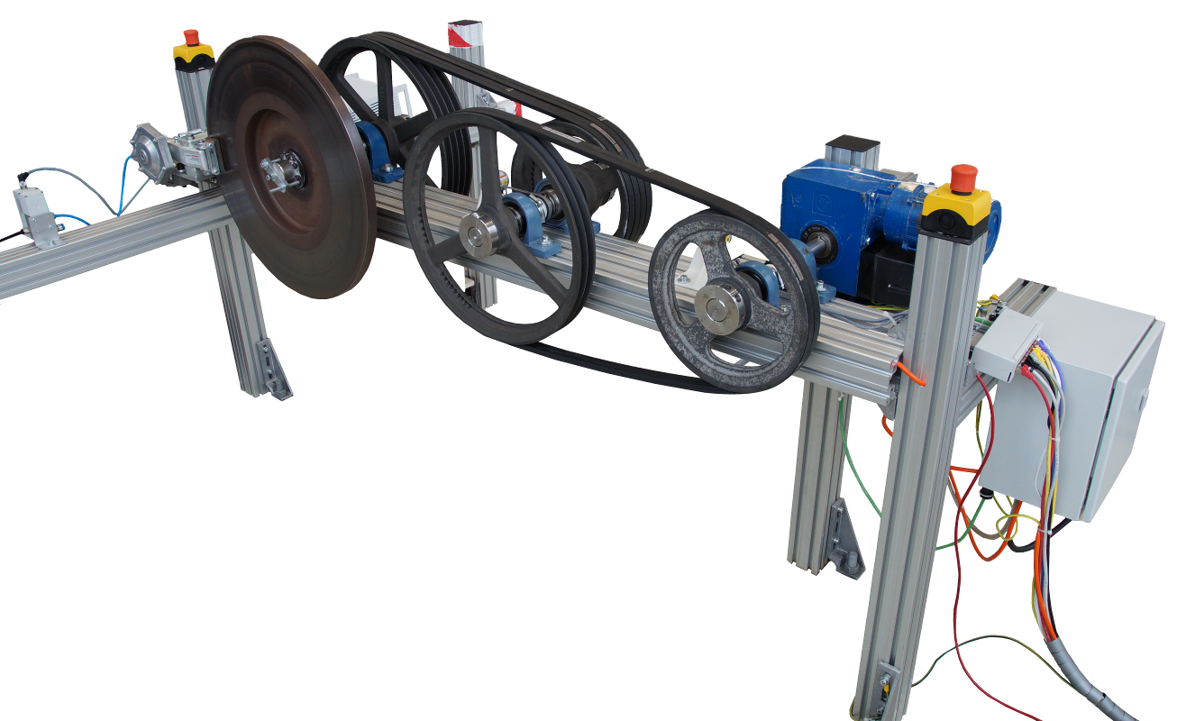

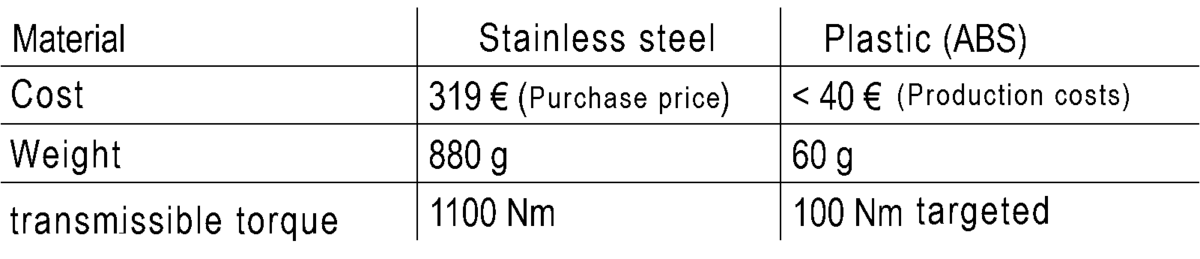

conventional solution from the company ETP Transmission AB

Example for 40 mm shafts

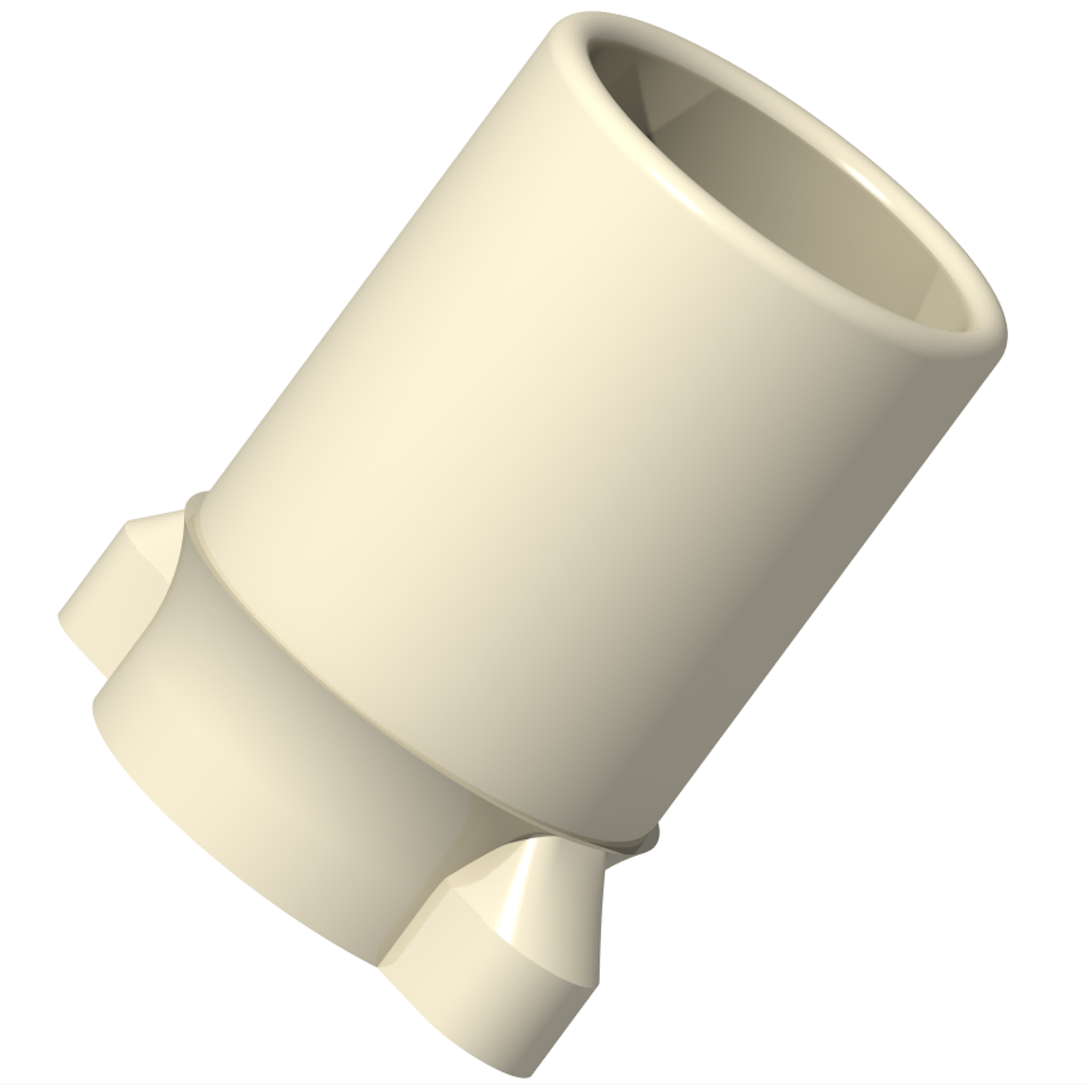

Plastic (ABS) solution

Problem of pressure tightness

FDM processes have imperfections and leaks in the material due to filaments that are not completely fused.

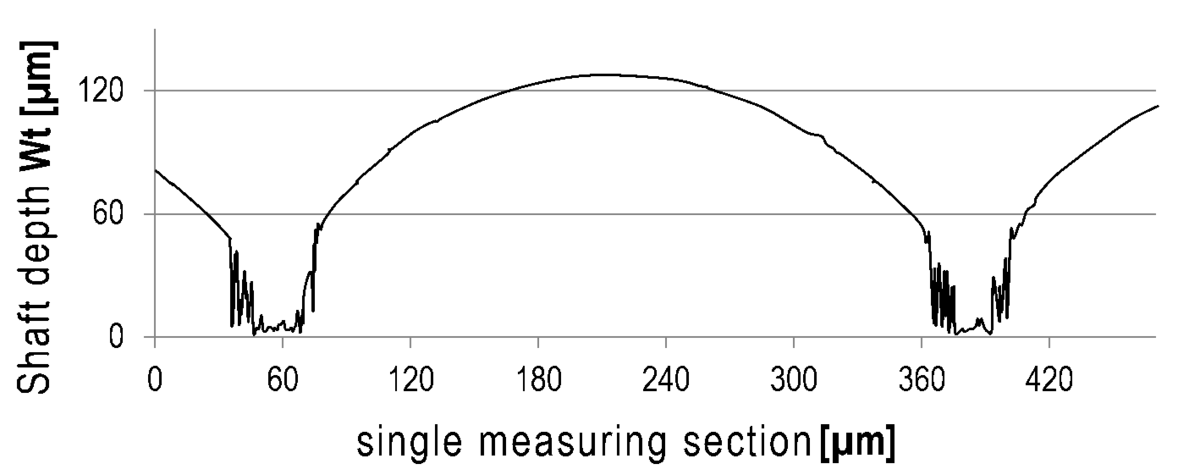

Problem of surface quality

Production-related waviness (Wt) and roughness (Rz, Ra) of the surface due to filament webs and extruder geometry.

Post-processing by surface post-treatment with solvent acetone; optimal treatment parameters (especially immersion time) are being researched for this purpose.

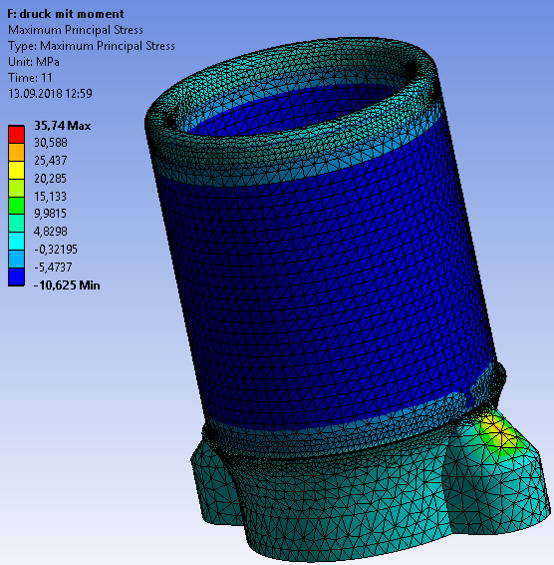

FE-Analysen

FE analyses were performed to optimize the component geometry and estimate the maximum operating pressure.

Experimental verification of the prototypes

Tests on our own test rig have shown that 20 Nm can be transmitted at an internal pressure of 5 bar. Further tests with regard to fatigue strength and increasing the internal pressure are in preparation.